ABOUT US

/Hongsheng Bio

Zhongshan Hongsheng Biological Technology Co., Ltd.

Zhongshan Hongsheng Biological Technology Co., Ltd. was established in 2003. The company is committed to the research and development, production and application of environmentally friendly textile printing and dyeing chemicals.Hongsheng has advanced modern laboratories, professional experimental testing equipment, as well as experienced product research and development personnel, professional product testing bases and customer service teams to solve various problems in washing, printing and dyeing for customers, and provide customers with, Environmentally friendly and stable products.

Industry experience

Customer service

Serve domestic and foreign brands

Warehouse area

Our Strengths

ADVANTAGE

Strictly abide by the process flow and process indicators, each batch of water reducing agent products has strict testing, strictly control the quality, and always prioritize product quality.

Under the guidance of the policy of "high quality, high requirements, and high treatment", the company strives to provide you with higher quality polycarboxylate admixture products and better services

Adhere to market orientation, focus on technological innovation and exquisite craftsmanship, and vigorously promote the management policy of "people-oriented".

HONOR

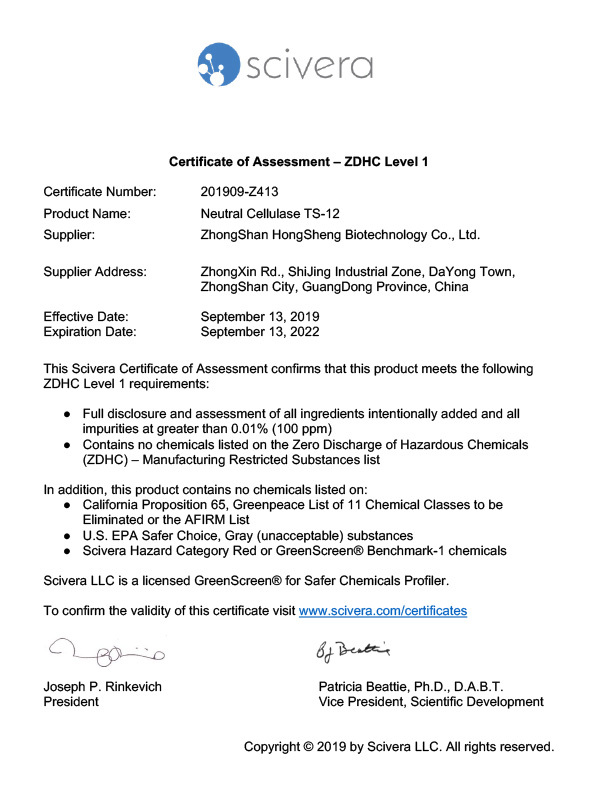

ZDHC-SV Certificate- Neutral Cellulase TS-12 201909-Z413

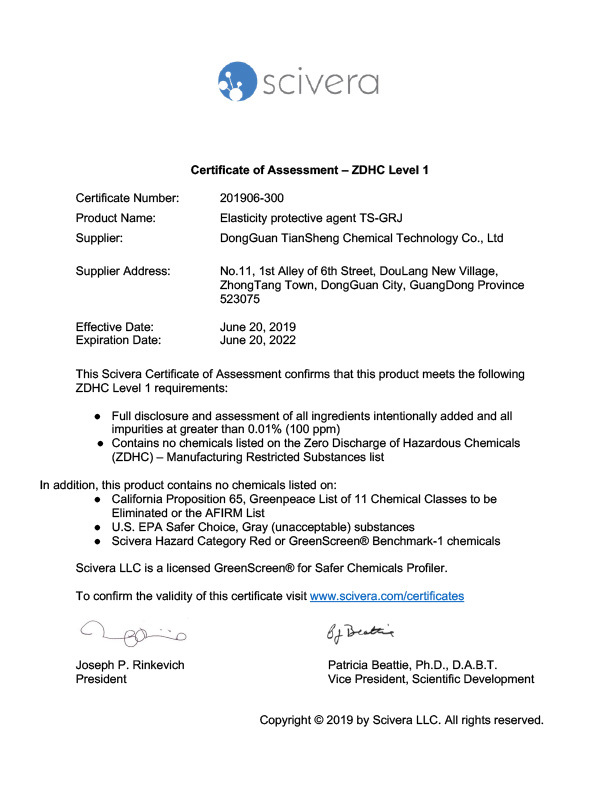

ZDHC-SV Certificate- Elasticity protective agent TS-GRJ 201906-300

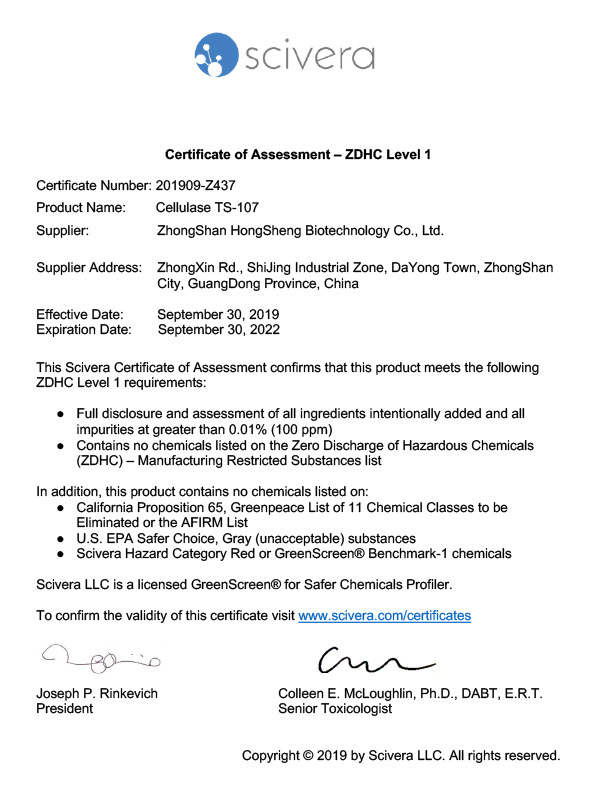

ZDHC-SV Certificate- Cellulase TS-107 201909-Z437

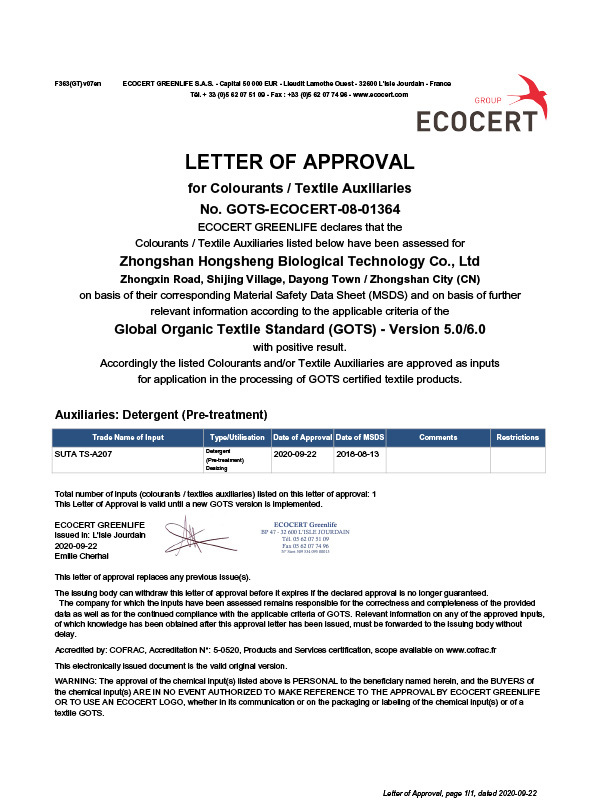

GOTS A207_2020-09-22

Pay tribute to the time coming, and start again with gratitude! An honorary ceremony for Zhongshan Hongsheng Bio to upgrade and set sail again!

After 17 years of unremitting efforts, Hongsheng has gradually grown from "no ridge, no house" to a well-known chemical additives supplier and service provider in the denim industry. Today, on November 24, 2020, Hongsheng Biotech held a ribbon-cutting ceremony for brand upgrade and opening. Witness with us another glorious historical moment in the development of Hongsheng, share with us this hard work, this joy, and welcome the birth of another brand new career.

这里是占位文字

Analysis on the Application of Chemical Dyes by Environmental Dyestuff Manufacturers

Analysis on the application of chemical dyes by environmental protection dye manufacturers 1. Select chemical dyes according to fiber properties. Because of their different properties, various fibers need to choose suitable chemical dyes when they are dyed. For example, when cotton fiber is dyed, because its molecular structure contains many hydrophilic hydroxyl groups, it is easy to absorb moisture and expand, can react chemically with reactive groups, and is more alkali-resistant, so you can choose direct, reduction, vulcanization, ice chemistry Dyes and reactive chemical dyes. Polyester is highly hydrophobic and is not resistant to alkali at high temperatures. Under normal circumstances, the above chemical dyes should not be used, but disperse chemical dyes should be selected for dyeing.

这里是占位文字